Includes: Wing, leash, and bag.

F-One STRIKE V3 Wing

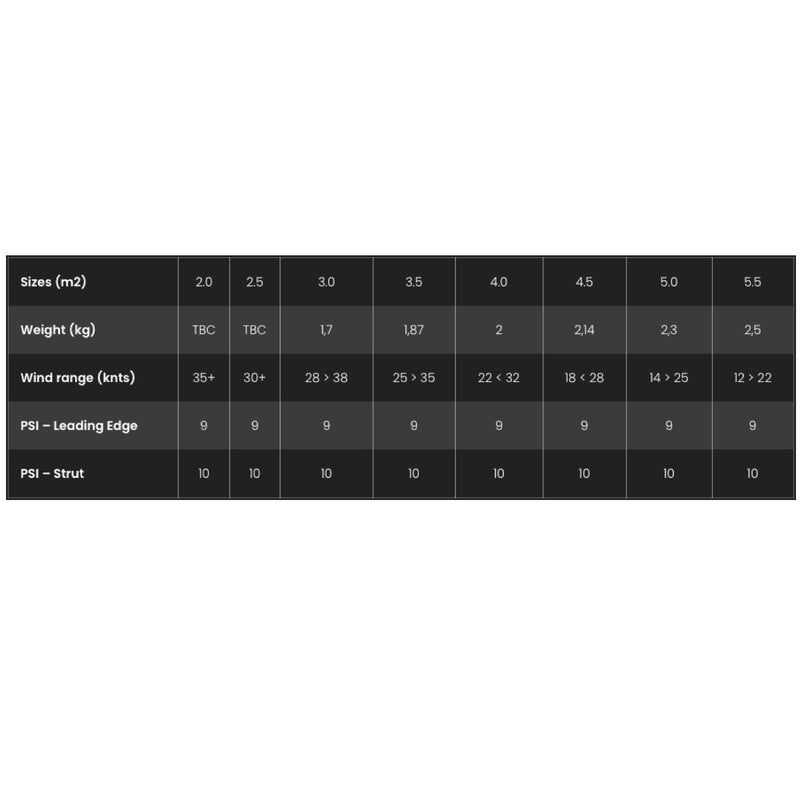

Available in: 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5 m²

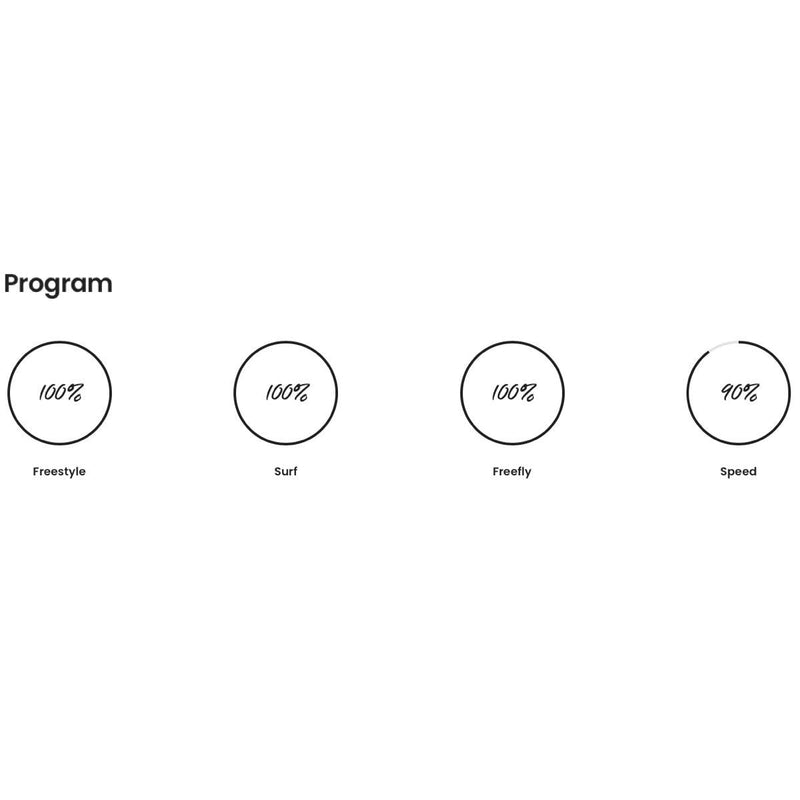

Conceived with the latest technologies and featuring a revolutionary design, the STRIKE V3 is the ultimate performance wing. Whether it’s freeride, freestyle, surfing or free fly, this state-of-the-art wing can do it all. The STRIKE V3 delivers unparalleled performance while guaranteeing comfort, stability, power, precision, durability, and the ability to go upwind quickly and efficiently in any winds.

• Revolutionary design for unprecedented performance.

• New HITEX and TECHNOFORCE for increased durability.

• Perfect control of the profile and deformations to guarantee comfort throughout the entire wind range.

• Improved power delivery and planing.

• Impressive upwind performances.

• Legendary lightness and stability in free fly.

• Perfectly balanced center of traction for an intuitive ride.

Key Features

For this third edition of our iconic STRIKE, the R&D team has worked on three areas: the materials, the placement of these materials and the design to improve performance and durability.

MATERIALS

The inflatable structure of the STRIKE V3 is made of HITEX 158g and 178g. This brand-new high tenacity polyester exclusive to F-ONE offers great resistance to elongation and therefore greater durability and performances.

The central strut is thinner in diameter thanks to the HITEX 158g and its independent valve that allows for a better control of its pressure. Its longitudinal reinforcements help command its shape and resistance.

The four central segments of the leading edge on each side of the strut are made of HITEX 178g, while the four outer segments nearer the wingtips are in 158g. Both materials are perfectly distributed to account for the different tensions, high pressures, and weight distribution in this area.

Since the beginning, we have also kept a thin leading edge diameter at the wingtips, bringing agility, comfort and glide, but also lightness and less inertia.

In addition to the new HITEX, we have developed a thicker TECHNOFORCE™/D2 in 66g for the trailing edge where tensions are important and resistance essential. The rest of the wing’s canopy is in TECHNOFORCE™/D2 in 52g.

WING DESIGN

Through Sail Engineering, we have conceived a completely new design; everything has been precisely thought-out to adapt the wing’s shape to the tensions and new materials.

Every panel on the STRIKE V3 is precisely laid to carry a specific load. The front of the wing combines horizontal panels separated by a vertical seam from the innovative radial center panels, which are mapped to accurately follow every load trajectory. The trailing edge is controlled by a vertical panel in 66g. Small radial cuts are also implemented on the wingtips and on the back of the strut to spread tensions. Aligning the fiber exactly along the load paths means that stretch can be controlled to a never-before-seen level on a wing.

Thanks to this precise load management, the wind range of the STRIKE is extended at both the high and low end, and the range of wind strengths where the wing feels perfect is greater than ever before.

With our staggered seams, the fabric and its seams work better to keep a smooth and efficient profile and the flying shape of the wing never deforms under load. The control of the profile is ideal, especially in the high end where stability is superb to ride fully balanced on both arms and in total comfort.

The new trailing edge tensions and radial cuts have brought incredible performance and control. Located on the back of the strut, our innovative Load Diffuser made of overlapping panels of hard Mylar and Dacron further helps maintaining the profile sleek and efficient, leading to the ultimate stability, performances, and longevity.

Every reinforcement on this wing has been reviewed to ensure durability and to save weight.

With the STRIKE V3 delivering stability beyond compare, we could have a flatter dihedral angle and thus reach a bigger projected area. In turn, the power and pumping abilities are even more improved for planing starts. This allows riders to use a smaller wing or board than before.

A new and slightly more compact outline with less span makes the STRIKE V3 easier to pump and ride. The center of traction has been perfectly placed right in front of the rider to guarantee a perfect balance on both arms.

Finally, all profiles have been revised to accommodate our new parameters. We were able to slightly reduce the V3’s profile thickness to bring even more comfort and control in strong winds. The high end potential of this STRIKE V3 is impressive, with an effective forward traction that won’t let you overexert yourself even when overpowered.

HANDLES

To further improve and optimize the rider’s control of the wing, we have rigidified our handles while keeping our original, lighter construction that doesn’t include any hard parts that could damage your wing, ding your board, or hit yourself. Our grippy, ergonomic and comfortable handles allow for some flexibility so your wrist is always in line with your arm.

This also gave us the opportunity to design the strut just as we liked. The front of it goes down straight away on your front hand before going up into the wing’s profile near your back hand. This leads to a more natural position to sheet in.

PERFORMANCE AND CONTROL

Thanks to its new design and precise fabrics placement, the STRIKE V3 is a masterpiece of aerodynamism. The perfect control of the profile and deformations guarantees unforgettable sessions.

We kept the STRIKE’s light weight and unique free fly stability so you can go for long surfs or downwinds without worrying about your wing and remain focused on your trajectory and foil.

In your hands, its legendary planing and pumping power are even better. When on the water, the upwind abilities are impressive with an incredibly consistent traction. This wing’s upwind performance is overall greatly enhanced throughout the wind range.

If you like to glide and go fast in total control and comfort, the STRIKE V3 will bring performance and stability. For freestyle and jumping, the height and lift will surprise you and all landings will be easier.

Virtually a brand-new wing, the V3 is an improvement of the V2 in all areas and pushes the performance of a wing into new territories. While it will surely satisfy riders of the highest level, the STRIKE is also incredibly accessible to anyone wanting to discover wing foiling.

The STRIKE V3 has it all and is yet again ahead of the game. Be the first to pick the third.

Technology

HITEX

To meet the specific needs of the development of wings and kites, and to offer a high-performance and durable product without using inaccessible materials, F-One developed HITEX, a new high tenacity polyester. Available in 158g, and exclusively for F-One in 178g, this new material is incredibly resistant to elongation and increases the durability of wings and kites.

HITEX is an innovative, high tenacity polyester fiber with an enhanced high-quality weaving and coating that increases the fabric's resistance. The 178g is. new weight and perfectly matches the needs of the center struts and center of its leading edge. The lighter158g is used in the leading edge tips.

Used throughout the inflatable structure of the wings and kites and designed to handle the high pressures when inflating, HITEX offers performance and resistance. Thanks to extensive Sail Engineering work, the R&D team has placed each weight of HITEX is different areas, allowing absolute control of the shape session after session.

Moving away from kite fabrics.

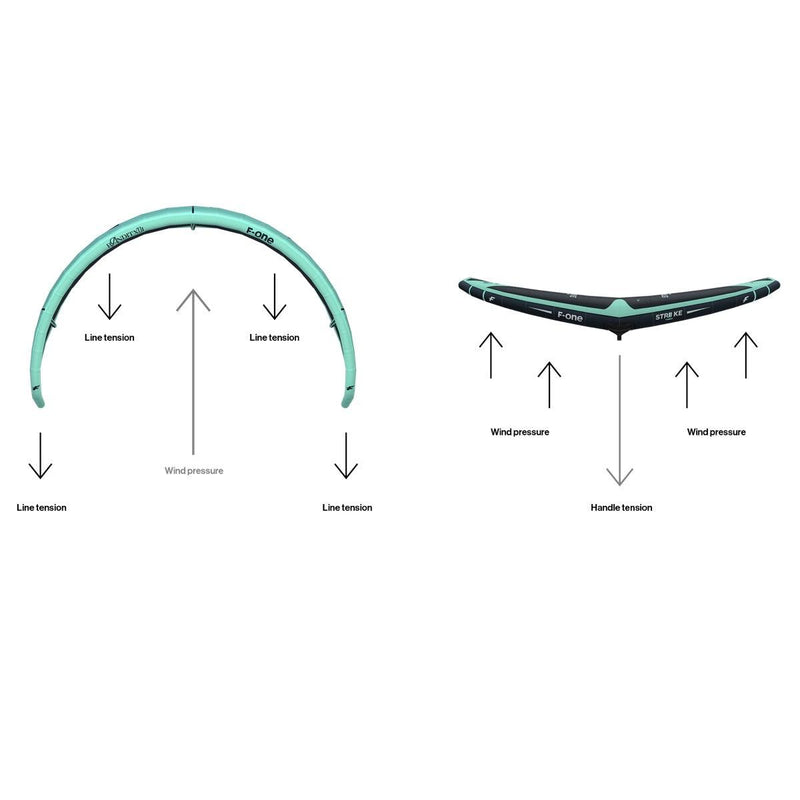

The efforts on a kite and on a wing are completely different.

Here, F-One is talking about the structure of their products. Even if the canopy is the surface that receives the wind, the leading edge and the struts of a kite or a wing make up the main structure, and therefore guarantee their qualities in flight.

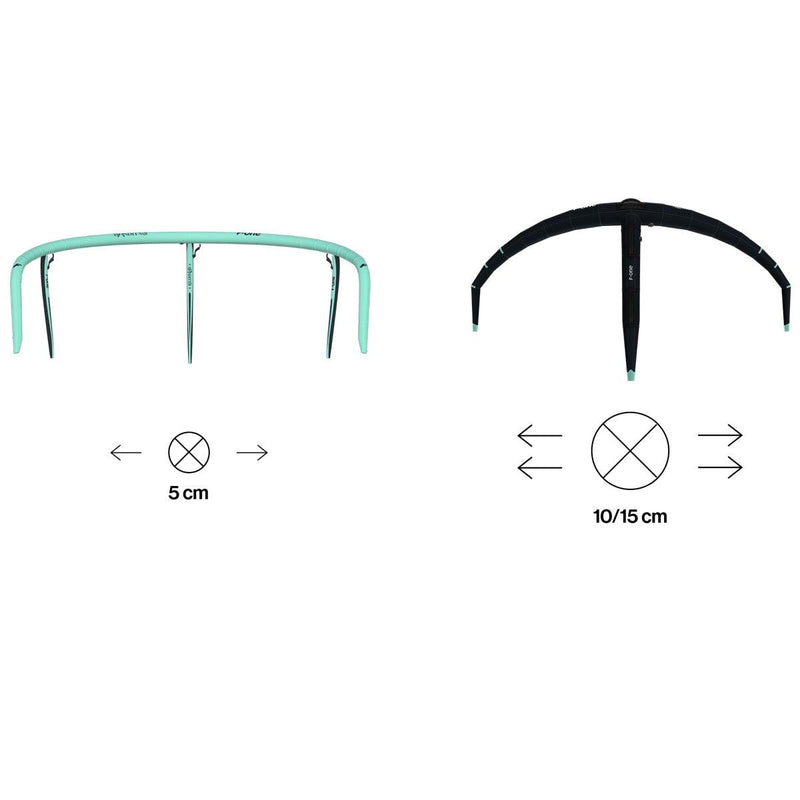

Held by two central handles, its two sides tend to deform under wind pressure. This is why the leading edge of a 5m² kite is between 10-15cm in diameter, while the leading edge of a wing with the same surface is about twice as big.

The larger the diameter of the leading edge, the larger the surface area of the fabric.

The air pressure in a volume is applied to the cm², under the formula:

pressure (Pa) = Force (N) / Surface (m²).

With the same inflation, the material of the leading edge of a wing receives a much higher pressure than that of a kite.

Moreover, in normal use, a wing is more often left flapping, dragged on abrasive surfaces, soaked in salt water, etc.

The ideal fabric for a wing has increased pressure resistance, limited deformation, and outstanding durability.

The High Tenacity Polyester: HITEX.

After working with our fabric manufacturer partners for a long time, we decided to use High Tenacity Polyester, a technical material offering a high resistance to elongation and superior durability.

Because each part of a wing does not require the same resistance to deformation, F-One developed two weights: 178g for the center of the wing and 158g for the wingtips.

The center of the wing must not deform in any way; it is the direct link between the user’s hands and the wind, and its rigidity guarantees stability of the wing while riding.

It is however interesting to keep the wingtips less rigid. Indeed, a controlled deformation of the wingtips allows to pump more efficiently, to absorb strong wind gusts, and thus to offer an increased comfort throughout the ride.

The use of this high tenacity fiber, in weights perfectly adapted to this sport and F-One's designs, has allowed us to reduce the diameter of the leading edge and to limit the use of additional reinforcements. This results in improved aerodynamics and reduced weight, offering better performances.

The HITEX is coated with PLASMA, an innovation exclusive to our supplier, which guarantees increased durability of the fabric. Coupled with high tenacity polyester fibers, it makes HITEX the most durable material on the market. F-One wings stay in good shape much longer and thus retain their original design and performance over time.

SAIL ENGINEERING

Sail engineering is the science of controlling the design and its behavior while flying. These features have been created with one goal in mind: Mastering the kite's loads to maintain the desired shape for the longest time.

1 – WARP TENSION LINE

Woven fabrics feature a longitudinal 0° yarn (Warp) and a transversal 90° yarn (Weft). Therefore, a fabric has great elongation resistance and strength capacities if you apply tension at 0° or 90° along the yarns. But it will deform and stretch when tension is applied at, let’s say, 45°.

2 – LOAD CONTROL PANELING

When engineering the load control paneling, F-One makes sure that fabrics panels are warp/weft oriented, meaning that the load path runs through the yarns. Fabric and seams are then in the best position to receive tensions and maintain the original kite shape.

3 – STAGGERED SEAMS

Most of the kite’s back lines tension is distributed through the trailing-edge panels and seams. As seams are significantly stiffer than the fabric they join, they tend to strain under loads and therefore deform the profile. The staggered seams break that line of tension by balancing the stiffness between seams and cloth, which helps distribute the load over a wider area and maintain the original shape even under high loads.

4 – FABRIC WEIGHT MANAGEMENT

F-One sails feature four different cloth weights, from 52 up to 155gr/m². Sail engineering allows us to control our shape and drive load tensions without using heavy fabrics or bulky designs, therefore we can reduce fabric’s weight and use. It results in a lighter, optimized kite.

TECHNOFORCE

TEIJIN's TECHNOFORCE is the most reliable high-density polyester fabric. Ut's tear-stopping structure using thin and hight tension yarn make the fabric ultra durable.

It has a great proven track record of lightness and durability.

REACTOR VALVE

The reactor valve offers a high flow connection that twist locks the pump hose to the kite for an easy and super-fast inflation and deflations at the push of a button.

It provides a high air flow rate between the struts and leading edge.

PRE LOADED CANOPY

From the beginning, F-One wings have had a unique canopy tension that can be compared to that of a harden up windsurfing rig. F-One wings are therefore “pre-tensioned” and made to adapt. This ideal tension of the trailing edge when riding guarantees much better performances upwind and in light winds.

ADAPTIVE WING DESIGN

While the industry trends towards the "all-rigid", F-One developed the Adaptive Wing Design, a unique concept offering the perfect balance between performance and comfort.

It is difficult and uncomfortable to handle a stiff, handheld wing in the high end, especially without a harness. A wing must be able to absorb that power, just like the mast bend or the opening of the leech in windsurfing or the depower in kitesurfing.

The Adaptive Wing Design transforms every gust into positive energy and enables a perfect control of the traction. This new wing is designed to adapt through a controlled deformation that allows the preservation of a high-performance profile and unprecedented stability throughout the entire range of use.

To reach this result, F-One worked on the leading edge and modified the shape of the central strut. Its cut is now segmented, allowing for an improved control of its curve and its deformations. We also enhanced the wing’s twist.

LOAD DIFFUSER

Located on the back of the strut, F-One innovative Load Diffuser made of overlapping panels of hard Mylar and Dacron further helps maintaining the profile sleek and efficient, leading Theo the ultimate stability, performances, and longevity.

RADICAL TIPS

Small radical cuts are also implemented on the wingtips and on the back of the strut to spread tensions. Aligning the fibre exactly along the load paths mean the stretch can be controlled to a never-before-seen level on a wing.

Looking for the lightwind model? Look into the F-ONE Strike CWC V3

Includes: Wing, leash, and bag.

F-One STRIKE V3 Wing

Available in: 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, 5.5 m²

Conceived with the latest technologies and featuring a revolutionary design, the STRIKE V3 is the ultimate performance wing. Whether it’s freeride, freestyle, surfing or free fly, this state-of-the-art wing can do it all. The STRIKE V3 delivers unparalleled performance while guaranteeing comfort, stability, power, precision, durability, and the ability to go upwind quickly and efficiently in any winds.

• Revolutionary design for unprecedented performance.

• New HITEX and TECHNOFORCE for increased durability.

• Perfect control of the profile and deformations to guarantee comfort throughout the entire wind range.

• Improved power delivery and planing.

• Impressive upwind performances.

• Legendary lightness and stability in free fly.

• Perfectly balanced center of traction for an intuitive ride.

Key Features

For this third edition of our iconic STRIKE, the R&D team has worked on three areas: the materials, the placement of these materials and the design to improve performance and durability.

MATERIALS

The inflatable structure of the STRIKE V3 is made of HITEX 158g and 178g. This brand-new high tenacity polyester exclusive to F-ONE offers great resistance to elongation and therefore greater durability and performances.

The central strut is thinner in diameter thanks to the HITEX 158g and its independent valve that allows for a better control of its pressure. Its longitudinal reinforcements help command its shape and resistance.

The four central segments of the leading edge on each side of the strut are made of HITEX 178g, while the four outer segments nearer the wingtips are in 158g. Both materials are perfectly distributed to account for the different tensions, high pressures, and weight distribution in this area.

Since the beginning, we have also kept a thin leading edge diameter at the wingtips, bringing agility, comfort and glide, but also lightness and less inertia.

In addition to the new HITEX, we have developed a thicker TECHNOFORCE™/D2 in 66g for the trailing edge where tensions are important and resistance essential. The rest of the wing’s canopy is in TECHNOFORCE™/D2 in 52g.

WING DESIGN

Through Sail Engineering, we have conceived a completely new design; everything has been precisely thought-out to adapt the wing’s shape to the tensions and new materials.

Every panel on the STRIKE V3 is precisely laid to carry a specific load. The front of the wing combines horizontal panels separated by a vertical seam from the innovative radial center panels, which are mapped to accurately follow every load trajectory. The trailing edge is controlled by a vertical panel in 66g. Small radial cuts are also implemented on the wingtips and on the back of the strut to spread tensions. Aligning the fiber exactly along the load paths means that stretch can be controlled to a never-before-seen level on a wing.

Thanks to this precise load management, the wind range of the STRIKE is extended at both the high and low end, and the range of wind strengths where the wing feels perfect is greater than ever before.

With our staggered seams, the fabric and its seams work better to keep a smooth and efficient profile and the flying shape of the wing never deforms under load. The control of the profile is ideal, especially in the high end where stability is superb to ride fully balanced on both arms and in total comfort.

The new trailing edge tensions and radial cuts have brought incredible performance and control. Located on the back of the strut, our innovative Load Diffuser made of overlapping panels of hard Mylar and Dacron further helps maintaining the profile sleek and efficient, leading to the ultimate stability, performances, and longevity.

Every reinforcement on this wing has been reviewed to ensure durability and to save weight.

With the STRIKE V3 delivering stability beyond compare, we could have a flatter dihedral angle and thus reach a bigger projected area. In turn, the power and pumping abilities are even more improved for planing starts. This allows riders to use a smaller wing or board than before.

A new and slightly more compact outline with less span makes the STRIKE V3 easier to pump and ride. The center of traction has been perfectly placed right in front of the rider to guarantee a perfect balance on both arms.

Finally, all profiles have been revised to accommodate our new parameters. We were able to slightly reduce the V3’s profile thickness to bring even more comfort and control in strong winds. The high end potential of this STRIKE V3 is impressive, with an effective forward traction that won’t let you overexert yourself even when overpowered.

HANDLES

To further improve and optimize the rider’s control of the wing, we have rigidified our handles while keeping our original, lighter construction that doesn’t include any hard parts that could damage your wing, ding your board, or hit yourself. Our grippy, ergonomic and comfortable handles allow for some flexibility so your wrist is always in line with your arm.

This also gave us the opportunity to design the strut just as we liked. The front of it goes down straight away on your front hand before going up into the wing’s profile near your back hand. This leads to a more natural position to sheet in.

PERFORMANCE AND CONTROL

Thanks to its new design and precise fabrics placement, the STRIKE V3 is a masterpiece of aerodynamism. The perfect control of the profile and deformations guarantees unforgettable sessions.

We kept the STRIKE’s light weight and unique free fly stability so you can go for long surfs or downwinds without worrying about your wing and remain focused on your trajectory and foil.

In your hands, its legendary planing and pumping power are even better. When on the water, the upwind abilities are impressive with an incredibly consistent traction. This wing’s upwind performance is overall greatly enhanced throughout the wind range.

If you like to glide and go fast in total control and comfort, the STRIKE V3 will bring performance and stability. For freestyle and jumping, the height and lift will surprise you and all landings will be easier.

Virtually a brand-new wing, the V3 is an improvement of the V2 in all areas and pushes the performance of a wing into new territories. While it will surely satisfy riders of the highest level, the STRIKE is also incredibly accessible to anyone wanting to discover wing foiling.

The STRIKE V3 has it all and is yet again ahead of the game. Be the first to pick the third.

Technology

HITEX

To meet the specific needs of the development of wings and kites, and to offer a high-performance and durable product without using inaccessible materials, F-One developed HITEX, a new high tenacity polyester. Available in 158g, and exclusively for F-One in 178g, this new material is incredibly resistant to elongation and increases the durability of wings and kites.

HITEX is an innovative, high tenacity polyester fiber with an enhanced high-quality weaving and coating that increases the fabric's resistance. The 178g is. new weight and perfectly matches the needs of the center struts and center of its leading edge. The lighter158g is used in the leading edge tips.

Used throughout the inflatable structure of the wings and kites and designed to handle the high pressures when inflating, HITEX offers performance and resistance. Thanks to extensive Sail Engineering work, the R&D team has placed each weight of HITEX is different areas, allowing absolute control of the shape session after session.

Moving away from kite fabrics.

The efforts on a kite and on a wing are completely different.

Here, F-One is talking about the structure of their products. Even if the canopy is the surface that receives the wind, the leading edge and the struts of a kite or a wing make up the main structure, and therefore guarantee their qualities in flight.

Held by two central handles, its two sides tend to deform under wind pressure. This is why the leading edge of a 5m² kite is between 10-15cm in diameter, while the leading edge of a wing with the same surface is about twice as big.

The larger the diameter of the leading edge, the larger the surface area of the fabric.

The air pressure in a volume is applied to the cm², under the formula:

pressure (Pa) = Force (N) / Surface (m²).

With the same inflation, the material of the leading edge of a wing receives a much higher pressure than that of a kite.

Moreover, in normal use, a wing is more often left flapping, dragged on abrasive surfaces, soaked in salt water, etc.

The ideal fabric for a wing has increased pressure resistance, limited deformation, and outstanding durability.

The High Tenacity Polyester: HITEX.

After working with our fabric manufacturer partners for a long time, we decided to use High Tenacity Polyester, a technical material offering a high resistance to elongation and superior durability.

Because each part of a wing does not require the same resistance to deformation, F-One developed two weights: 178g for the center of the wing and 158g for the wingtips.

The center of the wing must not deform in any way; it is the direct link between the user’s hands and the wind, and its rigidity guarantees stability of the wing while riding.

It is however interesting to keep the wingtips less rigid. Indeed, a controlled deformation of the wingtips allows to pump more efficiently, to absorb strong wind gusts, and thus to offer an increased comfort throughout the ride.

The use of this high tenacity fiber, in weights perfectly adapted to this sport and F-One's designs, has allowed us to reduce the diameter of the leading edge and to limit the use of additional reinforcements. This results in improved aerodynamics and reduced weight, offering better performances.

The HITEX is coated with PLASMA, an innovation exclusive to our supplier, which guarantees increased durability of the fabric. Coupled with high tenacity polyester fibers, it makes HITEX the most durable material on the market. F-One wings stay in good shape much longer and thus retain their original design and performance over time.

SAIL ENGINEERING

Sail engineering is the science of controlling the design and its behavior while flying. These features have been created with one goal in mind: Mastering the kite's loads to maintain the desired shape for the longest time.

1 – WARP TENSION LINE

Woven fabrics feature a longitudinal 0° yarn (Warp) and a transversal 90° yarn (Weft). Therefore, a fabric has great elongation resistance and strength capacities if you apply tension at 0° or 90° along the yarns. But it will deform and stretch when tension is applied at, let’s say, 45°.

2 – LOAD CONTROL PANELING

When engineering the load control paneling, F-One makes sure that fabrics panels are warp/weft oriented, meaning that the load path runs through the yarns. Fabric and seams are then in the best position to receive tensions and maintain the original kite shape.

3 – STAGGERED SEAMS

Most of the kite’s back lines tension is distributed through the trailing-edge panels and seams. As seams are significantly stiffer than the fabric they join, they tend to strain under loads and therefore deform the profile. The staggered seams break that line of tension by balancing the stiffness between seams and cloth, which helps distribute the load over a wider area and maintain the original shape even under high loads.

4 – FABRIC WEIGHT MANAGEMENT

F-One sails feature four different cloth weights, from 52 up to 155gr/m². Sail engineering allows us to control our shape and drive load tensions without using heavy fabrics or bulky designs, therefore we can reduce fabric’s weight and use. It results in a lighter, optimized kite.

TECHNOFORCE

TEIJIN's TECHNOFORCE is the most reliable high-density polyester fabric. Ut's tear-stopping structure using thin and hight tension yarn make the fabric ultra durable.

It has a great proven track record of lightness and durability.

REACTOR VALVE

The reactor valve offers a high flow connection that twist locks the pump hose to the kite for an easy and super-fast inflation and deflations at the push of a button.

It provides a high air flow rate between the struts and leading edge.

PRE LOADED CANOPY

From the beginning, F-One wings have had a unique canopy tension that can be compared to that of a harden up windsurfing rig. F-One wings are therefore “pre-tensioned” and made to adapt. This ideal tension of the trailing edge when riding guarantees much better performances upwind and in light winds.

ADAPTIVE WING DESIGN

While the industry trends towards the "all-rigid", F-One developed the Adaptive Wing Design, a unique concept offering the perfect balance between performance and comfort.

It is difficult and uncomfortable to handle a stiff, handheld wing in the high end, especially without a harness. A wing must be able to absorb that power, just like the mast bend or the opening of the leech in windsurfing or the depower in kitesurfing.

The Adaptive Wing Design transforms every gust into positive energy and enables a perfect control of the traction. This new wing is designed to adapt through a controlled deformation that allows the preservation of a high-performance profile and unprecedented stability throughout the entire range of use.

To reach this result, F-One worked on the leading edge and modified the shape of the central strut. Its cut is now segmented, allowing for an improved control of its curve and its deformations. We also enhanced the wing’s twist.

LOAD DIFFUSER

Located on the back of the strut, F-One innovative Load Diffuser made of overlapping panels of hard Mylar and Dacron further helps maintaining the profile sleek and efficient, leading Theo the ultimate stability, performances, and longevity.

RADICAL TIPS

Small radical cuts are also implemented on the wingtips and on the back of the strut to spread tensions. Aligning the fibre exactly along the load paths mean the stretch can be controlled to a never-before-seen level on a wing.

Looking for the lightwind model? Look into the F-ONE Strike CWC V3

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.